See the DCM Series perform simultaneous pipe cutting and beveling in a single operation

Overview

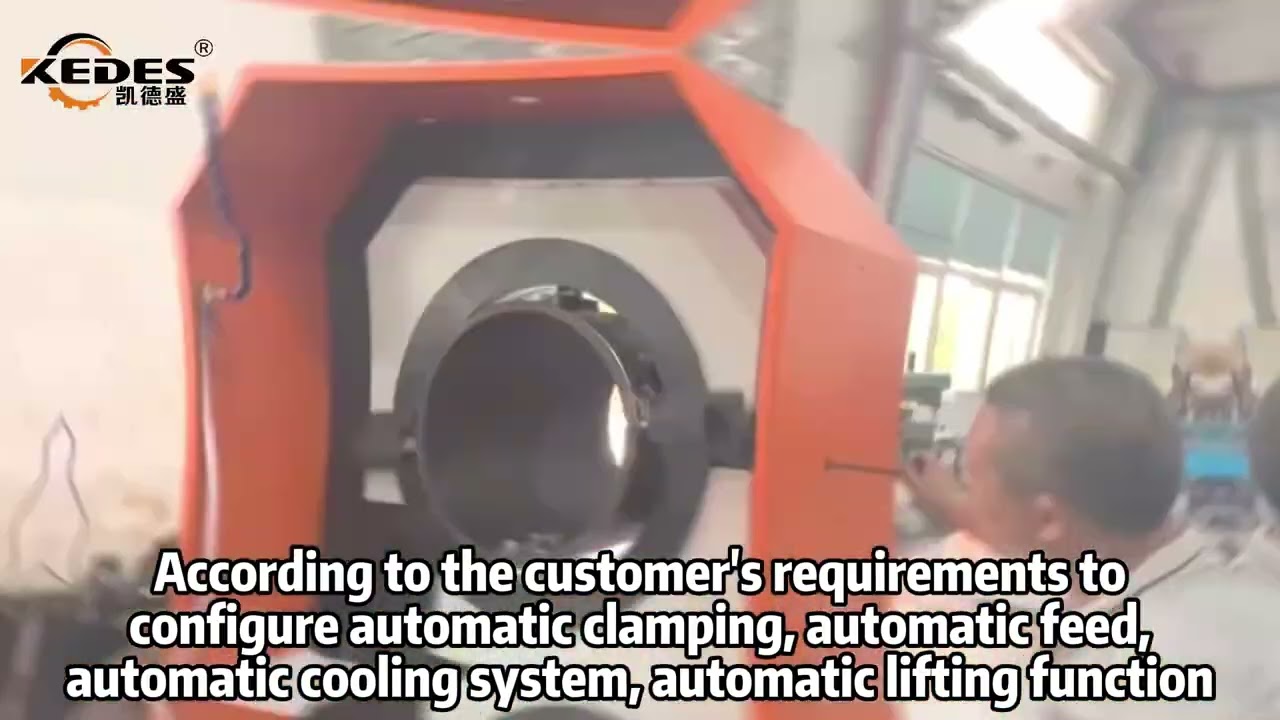

The DCM Stationary Series represents our premium workshop solution for high-volume pipe prefabrication. Unlike portable beveling machines that mount onto the pipe, these stationary units bring the pipe to the machine—providing superior rigidity, precision, and throughput for production environments.

Key Advantages

- Simultaneous operation - Cut and bevel in one pass, 50% time savings

- Electric self-centering - Automatic pipe alignment, no manual adjustment

- Cold cutting - Water-cooled, zero heat-affected zone

- Production ready - High throughput for shop fabrication

Why Choose Stationary Over Portable?

| Factor | Stationary (DCM) | Portable |

|---|---|---|

| Throughput | High volume, continuous | Single pipe, intermittent |

| Precision | ±0.1mm repeatability | ±0.3mm typical |

| Setup Time | Once per batch | Each pipe |

| Operator Fatigue | Minimal | Significant |

| Best For | Shop fabrication | Field work |

Operating Principle

- Load - Position pipe on V-rollers, slide into chuck

- Clamp - Electric chuck self-centers and grips OD

- Set - Adjust bevel angle and cutting depth

- Cut - Cutter head rotates around stationary pipe

- Unload - Release chuck, remove finished pipe

The entire cycle takes 3-8 minutes depending on pipe size, with minimal operator intervention.

Which Model Should You Choose?

For general pipe shops (up to 12” OD):

The DCM-325 handles the vast majority of pipe spool work in fabrication shops. It’s our most popular stationary beveler, offering the best balance of capacity, footprint, and cost. Ideal if you mainly work with Schedule 40/80 pipes in standard sizes.

For medium to heavy production (up to 16” OD):

Choose the DCM-426 if you regularly process 14-16” pipes or need extra wall thickness capacity (up to 25mm). Many power plant contractors prefer this model for its versatility across steam and process piping.

For large diameter work (up to 24” OD):

The DCM-630 is our flagship stationary machine for heavy industrial applications. Essential for offshore, LNG, and major petrochemical projects where 18-24” pipes are common.

Technical Highlights

Cooling System

- Closed-loop water circulation

- Maintains tool temperature <50°C

- Extends carbide insert life to 500+ cuts

Feed Control

- Adjustable feed rate (0.07-0.2 mm/rev)

- Balances surface finish quality against cycle time

Bevel Profiles

- Standard: 30°, 37.5°, 45° V-bevels

- Optional: J-prep, compound bevels

Customization Options

- Bevel Angle — Standard angles (30°, 37.5°, 45°), J-prep and compound bevels on request

- Voltage — 380V/50Hz standard, other configurations available

- Tooling Package — Standard or heavy-wall tooling for walls >25mm

- Automation — Pipe feeding system and DRO upgrades available